Environmental Corrosion Characteristics

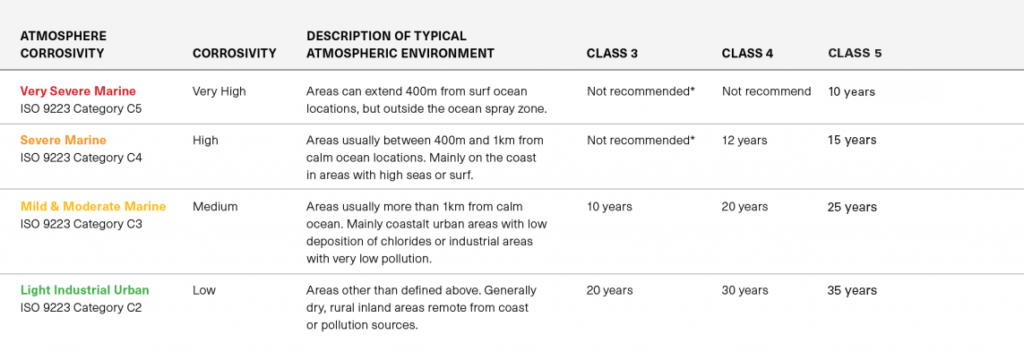

The above information is taken from ISO9223:2012(E) Corrosion of metals and alloys – Corrosivity of atmospheres – Classification, determination and estimation and AS4312:2008 Atmospheric corrosivity zones in Australia.

Above table to be used as a guide only. Due to the many factors influencing corrosion (prevailing wind direction, wind velocity, local topography etc.), it is very difficult to accurately determine the aggressiveness of a given environment. Corrosion zones can extend out further than stated above. It is recommended an inspection of the local environment and the condition of similar structures is undertaken. If unsure, professional advice should be obtained to aid in the selection of appropriate screw material/coating and its compatibility with building materials.

*300 series Stainless Steel fasteners may be suitable in these environments, with consideration given to material compatibility. Class 5 coated carbon steel screws are also available and may be suitable in ISO 9223 C5 environment.