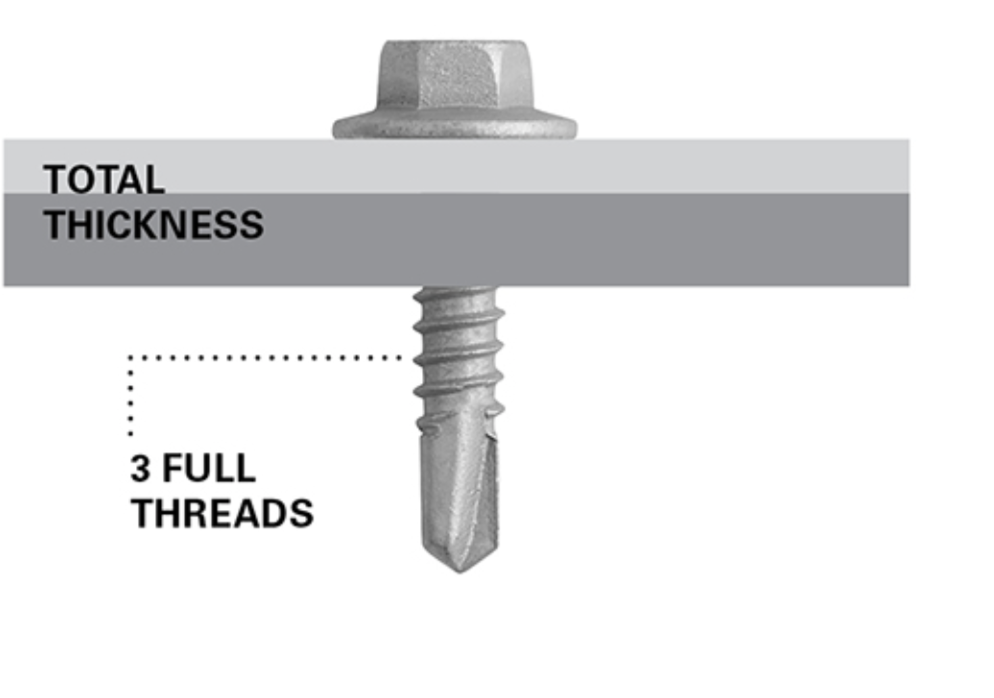

- The flute length of the self drilling screw should be greater than the total thickness to be drilled including any voids or spaces between sheets.

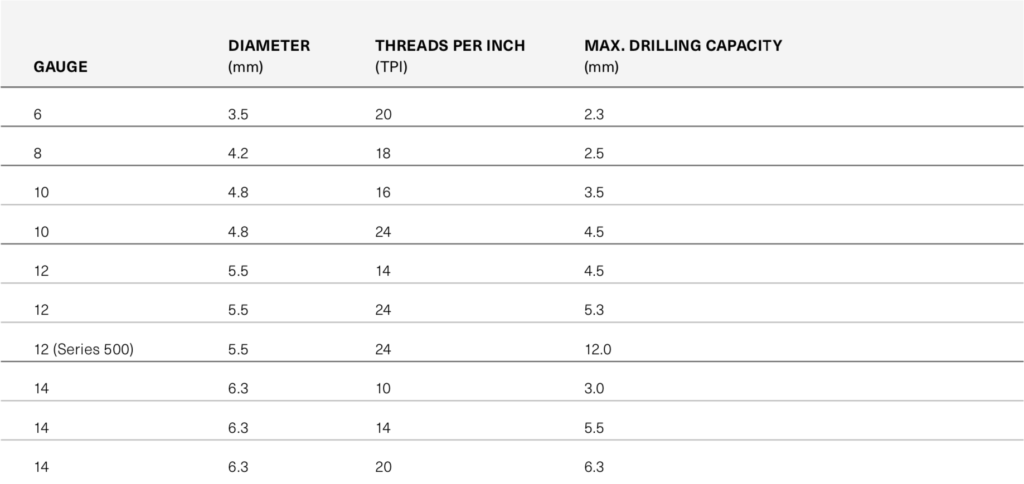

- Heavy drilling generally requires a fine thread and a relatively wide drill point, and fastening to thin metal generally requires a coarse thread with a relatively narrow drill point.

- When determining the fastener length required ensure there are at least 3 full threads protruded through the substrate material as shown right.

- As a general guideline when fixing to timber, the depth of penetration of screw into timber should be 5 × screw diameter. For example, if your using a 12 gauge screw which is 5.5mm then the penetration depth should be at least 27.5mm.

Drilling Capacity of Self Drilling Screws for Metal

As metal properties may vary, the above values should only be used as a guide only.

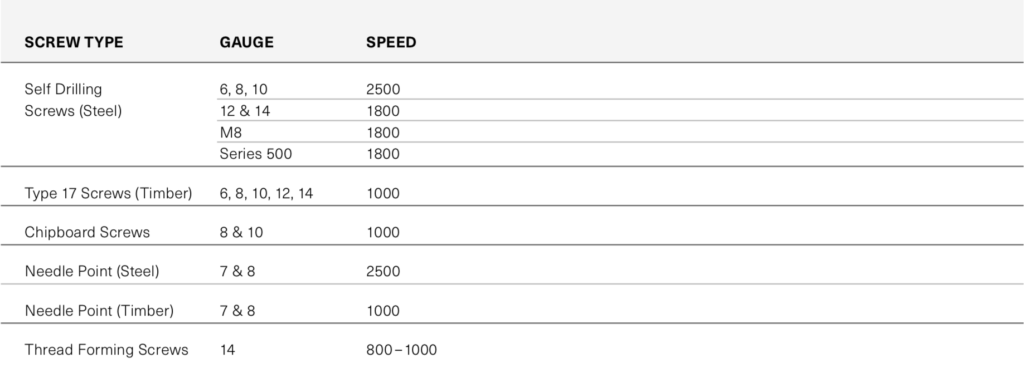

Recommended Screw Driving Speeds

Tri-Fixx recommend that an appropriate screw gun with depth gauge and clutch setting be used when installing self drilling screws. Tri-Fixx does not recommend the use of impact drivers to install self drilling screws.

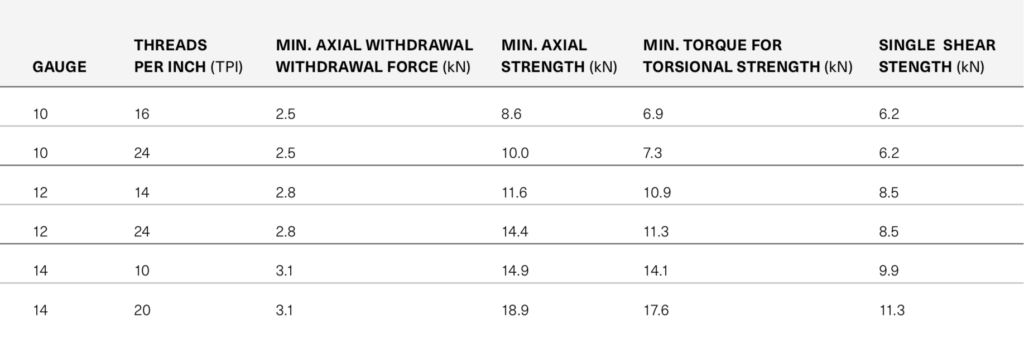

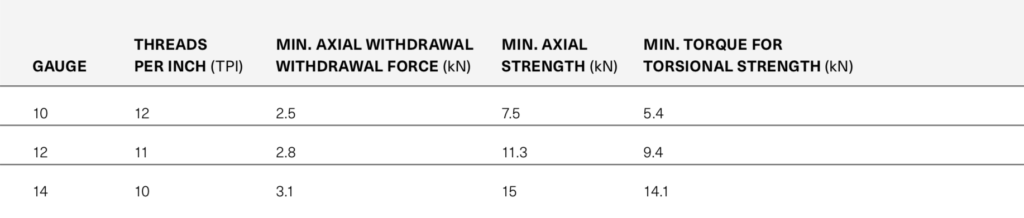

Mechanical Properties of Self Drilling Screws for Metal

Values shown are ultimate loads not recommended working loads.

Minimum axial withdrawal force is based on 1.5mm metal thickness (G450-Z350).

Mechanical Properties of Type 17 Screws for Timber

Values shown are ultimate loads not recommended working loads.

Minimum axial withdrawal force is based on F5 seasoned radiata pine.